Aspire Industrial Services Ltd. Health & Safety Policy

1.0 Organisational Structure

2.0 Health and Safety Policy

Aspire Industrial Services Ltd specialise in the supply of tools, plant, equipment, consumables, protective clothing and workwear to a vast array of clients, nationwide. We are committed to progressively improving the health and safety of our employees while fulfilling our commitment to our supply chain and clients. We strive to ensure that the health and safety of others is not adversely affected by our actions or inactions.

To do this we aim to:

- Create a positive culture that considers health and safety management as a key part of a successful and forward-thinking business.

- Set and review objectives and targets that address our significant health and safety

- Ensure that employees at all levels receive appropriate training and are competent to carry out their duties and

- Work with our supply chain and clients to promote workplace safety.

- Identify health and safety hazards within the workplace.

- Comply with the Health and Safety Policies set out by our clients and supply chain.

- Comply with the legal and other requirements to which we subscribe.

Aspire accepts that, as an organisation we have a responsibility to take reasonable account of health and safety of all persons who may be affected by its activities and will ensure that adequate resources will be made available in order to implement this Policy Document in full.

The policy will be kept under review and revised on an annual basis or where dictated by legislation.

Endorsed by:

C.Donnelly

Claire Donnelly

Managing Director

November 2019

Review: November 2020

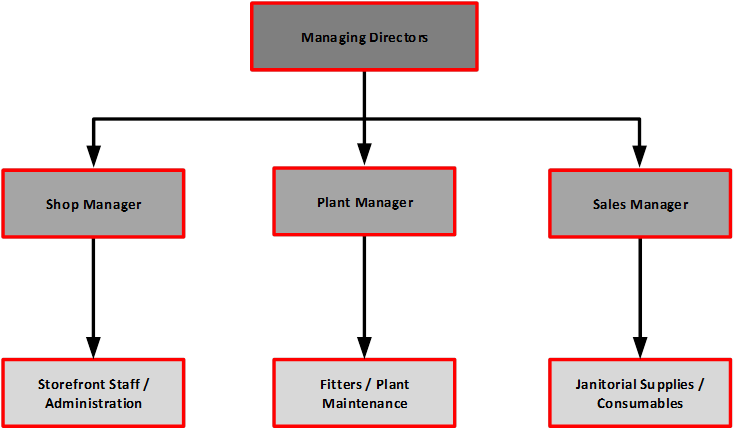

3.0 Responsibilities

We all have a responsibility for our own health and safety and the health and safety of others. The key responsibility for establishing an appropriate safety culture rests with all those who manage or supervise other persons. Each Individual member of staff has a responsibility for their own safety and for the safety of others who may be affected by their acts or omissions.

Aspire has identified roles with key health and safety responsibilities that must be fulfilled, so that the Company can achieve its safety objectives.

Managing Directors

The Managing Directors have ultimate responsibility for health and safety at work within the organisation and will take an active role in the implementation of this policy and publicly supporting its message throughout the company.

The will decide on the annual health and safety priorities of the company and ensure the allocation of adequate and appropriate resources. In conjunction with appointed safety consultants, the managing director shall ensure competent persons are appointed to assist in the execution of this policy at all levels.

The Managing Directors will ensure risk assessments are completed, safe systems of work are adhered to and emergency provisions are reviewed annually as a minimum and amended as necessary. If any changes are required then these changes must be actioned as soon as practicable. They will make suitable time and resources available to ensure the health, safety and welfare of employees and 3rd parties is not compromised.

All accidents/near misses occurring during the company activities should be reported directly to the Managing Directors in line with the company’s accident and incident reporting procedure and they will allow for the investigation of all incidents to discover the cause and eliminate reoccurrence where applicable.

The Managing Directors will identify training needs and review the on-going needs for statutory provisions such as first aid. All new permanent and temporary staff will receive appropriate safety induction training, which will be kept in the individual employee file.

The Managing Director is aware of the chief requirements of the HASAWA and other legislation relevant to the company. He will also have a mechanism in place to be able to keep abreast of any changes in the law.

Management

The Aspire Industrial Services Ltd management will ensure that all operations are undertaken as per the risk assessment pertinent to that activity. They will ensure that all parties under their control are aware of their obligations and to ensure an ongoing commitment to health and safety.

Management will ensure daily inspections are carried out in relation to quality and safety, with all findings and issues reported to the managing directors and logged accordingly.

Management are considered to be the link between the managing director and employees with any issues raised regarding health and safety, communicated throughout the organisation.

Management are the first line of communication for employees on matters relating to health and safety. They will ensure that all work is carried out in accordance with company procedure and approved working practises.

Management will notify the managing directors of all reportable accidents / near misses, in line with the company’s Accident and Incident Reporting Procedures. They will ensure that any remedial health and safety related actions raised during Inspections are implemented immediately.

Employees

Under the Health and Safety at work etc Act 1974; all employees have a legal obligation to take reasonable care of their own health and safety and that of others who may be affected by their actions. Employees have a responsibility to co-operate in the provision of safe working conditions and the observance of the requirements of the company safe working procedures, the Health and Safety at Work etc. act and this policy.

As a result, all Aspire Industrial Services Ltd employees are required to:

- Use the correct tools and equipment for the job; keep them in good working condition and use such equipment carefully and in accordance with any working instructions or training received.

- Use and take care of any personal protective equipment or clothing provided by way of statutory regulations or as detailed in a risk assessment.

- Avoid improvising which entails unnecessary risk and observe all specific warnings and instructions regarding the use of equipment or materials.

- Stop work when a hazardous situation is foreseen or created which may involve injury to you, other persons or damage to property and equipment.

- Report ALL accidents involving injury to persons or damage to property and other dangerous occurrences and “near misses” to the site supervisor or other person in charge.

- Ensure that reference is made to the Company’s COSHH procedures prior to using any material or substance or carrying out any operation which falls within the scope of the COSHH.

- Bring to the attention of your supervisor deficiencies in personal ability e.g. untrained to operate plant and equipment.

- Refrain from misusing or abusing welfare facilities.

- Take an active part in promoting the Company safety policy and safe systems of work.

- Carry out work activities in compliance with risk assessment and health and safety plan requirements including site rules.

- Set a good example and follow safe working practices and encourage others to observe the same.

Employees must report all hazardous situations, defects to plant / equipment and unidentified risks to company directors.

4.0 Arrangements and Safety Culture

4.1 General Training

All staff will receive the company induction on commencing their employment with Aspire Industrial Services Ltd. The introduction will include a briefing on the organisation’s Health, Safety and Environmental stance and specific requirements for the individual’s area of work.

Directors will conduct skills/competence profiling of employees in line with the current company requirements. All decisions made regarding will be included within meeting minutes and distributed. Training courses will be co-ordinated by Directors.

Records of all training will be held within the office and updated accordingly.

4.2 Employee Consultation

Aspire Industrial Services Ltd conducts regular worker consultation to ensure information is filtered throughout the company. This is to help ensure that all parties within the company are working together and communicating effectively. Worker consultation sessions will include recent health and safety matters, and any areas which may require to be improved. All staff will be given the opportunity raise any questions or queries they may have to regard to health and safety issues or general issues within the company.

4.3 Safety Inspection

Site inspections will be carried out on a daily basis by management. All inspections will be recorded and stored within the company office. The findings of the inspections will be kept electronically in a database which will identify common trends will be made available to management at the end of each year.

Inspections by management can be used as the basis for disciplinary action when gross misconduct of any kind is observed. Photographs may be taken on site to back up any issues raised/observations whilst on site and also may be used for disciplinary proceedings as deemed appropriate by management.

Directors are responsible for ensuring that hazards identified within site inspections, are actioned without delay.

4.4 Safety Performance Review

Health, Safety and Welfare are topics during safety update meetings directors and staff. During these meetings, feedback from recent inspections and preventative measures implemented will be discussed.

Company directors will be made aware of any Accidents / Incidents that have occurred within the last 7 days along with any preventative action / feedback in relation to the incident.

4.5 Accident Reporting

All reportable incidents and accidents that require first aid treatment or medical assistance will be logged in the company Accident Book.

As specified within the Reporting of injury, Diseases and Dangerous Occurrences Regulations 2013, Aspire Industrial Services Ltd will notify HSE if an employee suffers any of the following:

- A fracture (other than to fingers, thumbs and toes)

- An Amputation

- An injury likely to lead to permanent loss of sight or reduction in sight

- A crush injury to the head or torso causing damage to the brain or internal organs

- Serious burns (including scalding) which:

- Covers more than 10% of the body

- Causes significant damage to the eyes, respiratory system or other vital organs

- Scalping requiring hospital treatment

- A loss of consciousness caused by head injury or asphyxia

- An injury arising from working in an enclosed space which:

- Leads to hypothermia or heat-induced illness

- Requires resuscitation or admittance to hospital for more than 24 hours

4.6 Accident Investigation

Where an employee suffers an injury which results in them being absent from work, or unable to perform their normal work duties, for more than seven consecutive days, this will be reported under RIDDOR 2013. This seven day period does not include the day of the accident, but does include weekends and rest days. The report must be made within 15 days of the accident.

Where required, the Managing Director will ensure that an investigation will be carried out as soon after the incident as is reasonably possible. In any event this will be no later than 72 hours after the incident. The incident investigation process may include:

- Taking of photographs – Interview of injured party(ies)

- Taking of samples – Interview Witnesses

- Visitation to the accident site – Interview fellow employees

- Consultation with contractor (if applicable) – Doctor/GP assessment

4.7 Emergency & Contingency Plans

Aspire Industrial Services Ltd is dedicated in being proactive when risk management is involved however we are aware that certain risks are out of our control. We therefore believe that in such an occurrence any emergencies can be controlled effectively with effective recovery operations implemented immediately.

Our use of the following can aid speed business recovery:

- Successful chain of command and communications strategy, including an agreed means of alerting all personnel and the emergency services, whether or not they are already present, to an incident.

- Efficient procedures for communicating with visitors including those in areas not affected.

- Unimpeded access for the emergency services.

With the help of these key actions, Aspire Industrial Services Ltd strongly believe that many foreseen and unforeseen circumstances can be dealt with in a highly effective manner.

4.8 Local Authority Liaison

The Local Environmental Health Department or the Health and Safety Executive (HSE) are responsible for ensuring that health and safety legislation is implemented within the workplace, with safety standards maintained to protect both employees and 3rd parties affected by the work activities of Aspire Industrial Services Ltd.

In the event of a visit by an Environmental Health Officer or HSE Inspector, it is important to ensure that they receive the appropriate information. Any employee dealing with the enquiry / visit from an inspector must co-operate at all times. The Managing Director should be notified of any such visits as soon as possible.

4.9 Safety Incentives and Sanctions

Any suggestions made by employees that have a significant safety affect are welcomed and acknowledged by the Managing Director.

Any person who intentionally or recklessly disregards the company Health and Safety Policy or its associated site agreements and procedures will be disciplined in line with the Companies Disciplinary Procedures.

4.10 Visitors

So far as is reasonably practicable, routes and areas of the premises used by visitors will be and will be maintained in a safe condition.

Our risk assessments take into account all those who may be exposed to hazards in our workplace, including visitors. Any hazards/hazardous locations are marked with suitable warning signs and hazard information is provided if necessary. Staff are expected to take responsibility for visitors and to notify directors if they consider anyone to be an unauthorised visitor.

4.11 First Aid Arrangements

Aspire Industrial Services Ltd, as required by the Health and Safety (First-Aid) Regulations, provide:

- Adequate and appropriate equipment and facilities for the rendering of first-aid to its employees if they are injured or become ill at work

- Adequate and appropriate numbers of suitable persons for the rendering of this first-aid

- Information to employees of the first-aid arrangements to include the location of equipment, facilities and personnel.

First aid boxes are made available to employees throughout our main office and on every site.

All first aid supplies will be:

- Of a suitable size and construction and appropriately marked (white cross on a green background).

- Sited, so far as is reasonably practicable, in clearly identifiable and readily accessible but secure locations, convenient to all areas, in a clean environment and convenient to washing facilities.

- Stocked with a sufficient quantity of suitable first-aid materials and nothing else.

- Regularly checked by a member of staff to ensure there are sufficient quantities of materials in usable condition.

- Provided to be carried in each company vehicle

4.12 First Aid Training

The Managing Director will arrange first-aid training in accordance with the Guidance to the HSE Approved Code of Practice. Training of new first-aiders will be undertaken by individuals attending external courses conducted by approved training providers.

Training for the re-qualification of first-aiders, where there is a continuing need for their service, will similarly be conducted by approved training providers.

In recognition of the anticipated infrequent use first-aiders will make of their skills during the period of their qualification (3 years maximum) and to counter the inevitable skill decay. A requalification course will be offered in the last three months before expiry of the certificate held.

4.13 Emergency First Aid

There will be circumstances where a fully trained 1st Aider is assessed as not being necessary, e.g. where the injury risk is low or there are few staff present. In this instance, an individual trained in Emergency First Aid will be suitable.

4.14 Site Welfare

Aspire Industrial Services Ltd recognises and accepts its responsibilities in relation to the provision of health and welfare facilities on site and in particular the requirements contained within the Construction (Design and Management) Regulations.

Aspire Industrial Services Ltd will ensure that suitable and sufficient welfare facilities have been provided for our employees. and made available for everyone to use, including visitors. These facilities will include:

- Protection during inclement weather.

- Storage of personal clothing.

- Storage of protective clothing.

- The accommodation for clothing shall include or allow for facilities for drying clothing.

- Taking meals with seating accommodation and means for heating water.

- Mean of heating food e.g. gas ring, electric ring, or microwave oven.

- Suitable and sufficient flushing toilets.

- Suitable and sufficient washing facilities, to include hot and cold, or warm running water.

The premises will have adequate washing facilities, which will include:

- Wash basins which allow operatives to easily wash hands and forearms.

- Soap and towels or dryers.

- Hot and cold (or warm) water, which shall be running water wherever practicable.

Washing facilities must be near any mess room or toilet unit on site. They must be kept in a clean and serviceable condition.

Drinking water will be provided at a convenient point on every site and will be marked “drinking water” unless this is obvious. Where appropriate, drinking cups will be provided for drinking water.

A suitable and sufficient number of toilet units will be provided and will be connected to the main sewage system

4.15 Fire

Premises and Visitors

The premises is fitted with an alarm and call point system to raise the alarm in the event of a fire.

Should the alarm sound, employees and visitor should evacuate to the assembly point located in front of the premises. All visitors are expected to follow the direction of employees. No member of staff should travel further into the building in order to look for a visitor who may be unaccounted for.

The assembly point is located in front of the premises, on the pavement area on Kelvin Avenue.

Extinguishers

The following table in clearly shows the recommended types of extinguisher that should be used for the different types of fires that can occur within the workplace. employees should familiarise themselves with this information so that they may deal any incidents effectively and help prevent harm to themselves or any other members of the public, staff and clients.

Table of Recommended Extinguishing Agents

| FIRE TYPE | WATER | FOAM | CO2 | POWDER |

| Class A: Cardboard, Paper, Wood, Textiles (anything organic) | Yes | Yes | No | No |

| Class B: Flammable Liquids (e.g. petrol, oils, paints) | No | Yes | Yes | Yes |

| Class C: Fires involving flammable gases (e.g. propane) | No | No | Yes | Yes |

| Class D: Fires involving metals (specialist extinguishers required) | No | No | No | No |

| Live electrical equipment | No | No | Yes | Yes |

|

UK Colour Code |

RED | CREAM | BLACK | BLUE |

Please Note:

The new European Standard (BS EN3), which came into force on 1st January 1997, requires all new fire extinguishers for use in European countries to have 95% of the body painted red. However, in line with familiar UK practice, BS7863 allows manufacturers to affix coloured identification panels according to the UK colour code system shown in the above table.

All existing full body colour BS5423 extinguishers may still be used in workplace, until they are no longer serviceable. Careful integration of new European Standard BS EN3 extinguishers is therefore required, to avoid confusion.

Flammable Liquids

All dispensing and use of flammable liquids will be done in a secure area with adequate natural or mechanical ventilation. Our workers are encouraged to take their regular breaks when working with such liquids.

Every effort is made to prevent spillages of these flammable materials. However, if such an incident was to occur the workers must contain spillages using sand or flame suppressant chemicals, keep all containers closed to stop any further mixing of chemicals, control possible ignition sources and ensure no-smoking rules are obeyed. If their procedures are adhered to, then safe management of the situation is likely.

A COSHH risk assessment sheet will be made available with all flammable liquids, to ensure the liquid is used and stored in the correct way, and all control measures are in place to prevent any harm being caused by the liquid.

4.16 Risk Assessment

The Management of Health and Safety at Work Regulations require all employers to access the risk to workers and any others who may be affected by their actions. Risk assessment involves identifying the hazards present in any operation and evaluates the extent of the risk involved, existing controls, precautions etc. being considered.

All persons likely to be affected by the risks detailed in the assessment are given specific information and details of any necessary control measures.

The natural progression from task risk assessments is for a method statement to be developed. The method statement will form part of the overall safe system of work which can be defined as a formal procedure which allows a specific task to be carried out safely, after a systematic examination of the task has identified and eliminated all the associated hazards, or at least minimised the risk to an acceptable level.

There is a need for all concerned to consider the following elements of the system of work:

- Task assessment

- Hazard Identification

- Safe Methods of Work

- Implementation

- Monitoring Arrangements

The company acknowledge that the Health and Safety at Work etc Act requires employers to ensure that their employees and others on their premises are not exposed to health and safety risks.

4.17 Plant and Equipment

The Provision and Use of Work Equipment Regulations (PUWER) applies to the safety use of the work equipment provided to our employees. To minimise the risk of injury from work equipment, we have put in place arrangements for the assessment of risks and have created appropriate control measures to minimise the risks identified.

Our control measures will include the following arrangements and procedures:

- A full assessment of all equipment purchased;

- All equipment purchased will comply with any relevant product safety standards;

- All hired equipment will comply with the regulations and will include the provision of comprehensive information on safe use and appropriate calibration certificates.

- Details of inspection of equipment that could give rise to serious injury;

- Adequate and identifiable means of isolation where appropriate;

- The provision of suitable and effective safety devices and controls;

- Suitable training.

Company Directors will ensure that all plant and equipment that requires statutory testing and examination has been placed on system for routine maintenance and testing. Where reasonably practicable, we will adapt work equipment for those employees with disabilities providing this creates no additional hazards.

Specialist contractors carrying out maintenance and testing tasks will be vetted to ensure that they are competent to carry out the work in accordance with health and safety requirements.

4.18 Personal Protective Equipment

Aspire Industrial Services Ltd recognise that the use of Personal Protective Equipment is a last resort for all work activities. Specific assessments to comply with the Personal Protective Equipment at Work Regulations will be carried out by the Managing Director.

For all activities requiring the use of specialist PPE, a record will be made of the protective equipment issued and the individuals involved. All PPE required, by the risk assessment for the activity, will be provided without the charge as stated within the law.

All activities requiring the use of PPE will be monitored and any item found unsuitable or damaged will be replaced as necessary. Only PPE that complies with the relevant British or European standards will be purchased. Where appropriate, only ‘CE’ marked PPE (and replacement components of PPE) will be purchased. PPE will be selected which does not interfere with other items of equipment. The PPE used will be maintained and replaced as necessary to ensure its effectiveness, including cleaning, disinfecting, testing and repair.

4.19 Working at Height

Any work at height is considered to be dangerous and every job that involves working that height must be dealt with accordingly.

Alongside risk assessments, Aspire Industrial Services Ltd strongly believes that the provision of adequate equipment and use of regular comprehensive training can effectively help with the implementing of a safety culture within the organisation. Training, such as PASMA, IPAF and internal ‘Working at Height’ toolbox talks is provided to our employees, to give them the skills for safe working at height.

Ladders should only be considered where the use of other more suitable work equipment is not appropriate and where they are used as a work place this should be for light work of short duration only.

4.20 Control of Substances Hazardous to Health (COSHH)

As the Company undertakes operations that involve the use / supply of substances that may be hazardous to health, the Control of Substances Hazardous to Health (COSHH) Regulations are of relevance.

Our arrangements, currently in place, for the satisfying of the above regulations, include:

- Making a written assessment of the risks to determine the action needed to meet the requirements of the regulations.

- Adequate control of exposure which must be achieved by means other than the use of personal protective equipment (PPE) as far as is reasonably practicable.

- Provision of approved respiratory protective equipment (RPE) when necessary.

- Provision of suitable protective clothing and equipment when necessary.

- Control measures to be properly used and maintained.

- The provision of the necessary instruction, information and training.

- Monitoring and health surveillance procedures where necessary for protecting the health of worker.

- Provision of suitable approved hygiene facilities.

- Provision of practical means to prevent exposure of the public to hazardous substances.

- Contracting the services of other specialist companies or individuals as necessary, to comply with appropriate regulations, Approved Codes of Practice, Guidance Notes, European and British Standards, etc.

Aspire Industrial Services Ltd will provide sufficient information to employees and other who may be exposed to any risk generated using substances or because of work activities. Up to date product information will be obtained from suppliers.

4.21 Manual Handling Assessments

Manual Handling means the transporting or supporting of a load, and includes lifting, pushing and moving objects by hand or using bodily force. Unskilled manual handling is the cause of many workplace injuries and accounts for around 25% of all reported accidents.

Wherever possible the need for manual handling should be avoided or reduced. Where manual handling tasks cannot be avoided and where health and safety risks have been identified, a detailed assessment will be completed, as required by the Manual Handling Operations Regulations. Assessments will consider:

- The task

- Individual capability

- The load

- The working environment

If a formal assessment is required, it will identify any remedial actions needed to reduce the risk to the employees whilst carrying out that task, and will also consider any special class of individuals who may be at risk from that activity (e.g. pregnant women, asthmatics etc).